Have you ever wondered about those sleek, durable surfaces gracing contemporary kitchens and stunning facades? Chances are, you’ve encountered sintered stone. It’s a material that feels both ancient and incredibly futuristic, born from processes that mimic the Earth’s own geological transformations. This isn’t just another pretty surface; it’s a testament to human ingenuity, taking natural elements and elevating them to something truly extraordinary. It’s a story of innovation, durability, and breathtaking beauty, all rolled into one remarkable product. Let’s dig in and see what makes this material so special.

For centuries, natural stone like marble and granite reigned supreme in architecture and design. Their beauty is undeniable, but they come with their own set of challenges – porosity, susceptibility to etching, and considerable weight. Then came engineered stones, like quartz, offering some improvements. But the true game-changer, the material that really pushes the boundaries, is sintered stone. It represents a significant leap forward, offering unparalleled performance and aesthetic versatility. It’s not just a trend; it’s a fundamental shift in how we think about and utilize surfaces in our homes and commercial spaces. Imagine a surface that’s virtually indestructible, yet looks like the most exquisite marble or the most rugged concrete. That’s the promise of sintered stone, and it’s a promise it absolutely delivers on.

What Exactly is Sintered Stone? Unpacking the Science

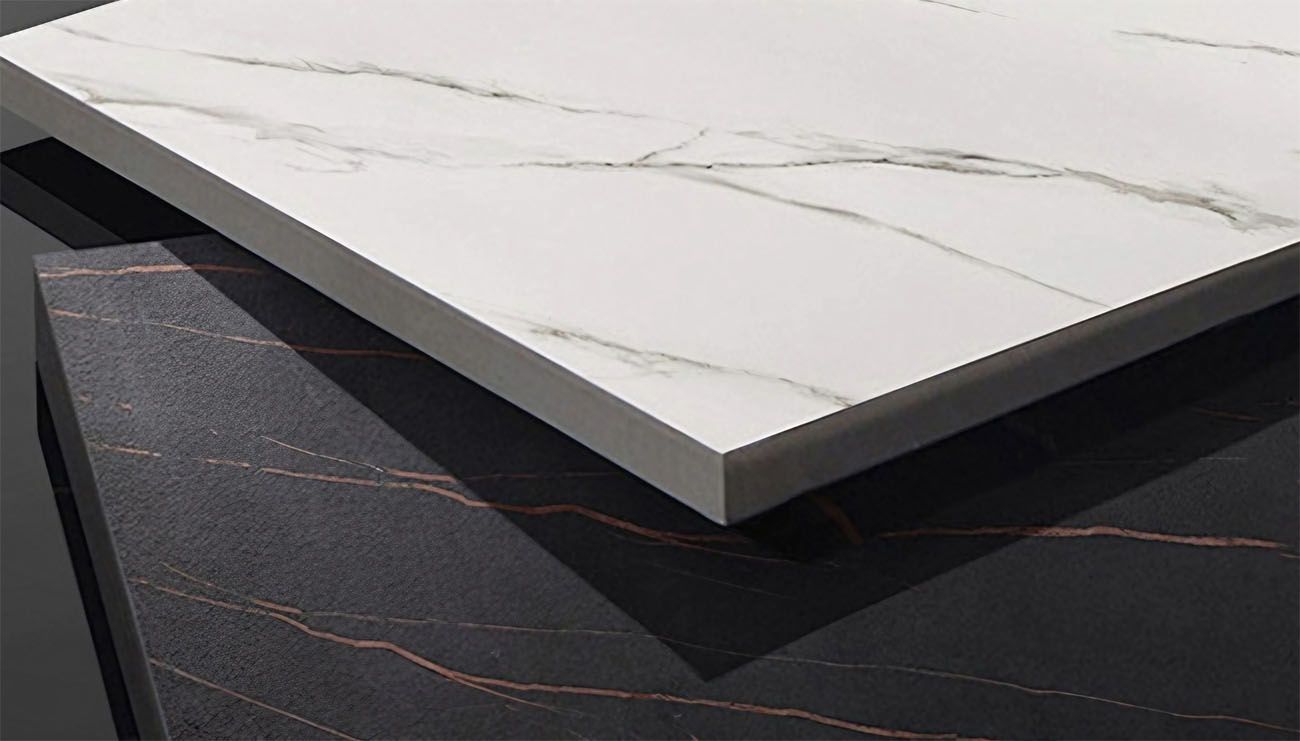

At its heart, sintered stone is a man-made product crafted from a blend of natural minerals. Think of it as a super-compressed, super-heated version of the very materials found deep within the Earth. The process, known as ‘sintering,’ involves subjecting these raw materials – things like feldspar, silica, and natural mineral oxides – to extreme heat and pressure. We’re talking temperatures often exceeding 1200°C (2200°F) and pressures that compact the material significantly. This intense treatment mimics the natural metamorphic processes that create granite and other hard rocks over millions of years, but it’s done in a factory, in a matter of hours. The result? A non-porous, incredibly dense material with properties that surpass many natural stones. It’s a truly fascinating convergence of geology and advanced manufacturing. Because it’s so dense, it doesn’t absorb liquids, making it stain-proof, and it’s incredibly hard, so it resists scratches and impacts. It’s like giving nature a little helping hand to create something even better.

From Humble Beginnings: The Genesis of Sintered Technology

While sintered stone as we know it today is a relatively recent innovation in the design world, the concept of sintering is far from new. It’s been used for centuries in various forms, from ceramics and metallurgy to creating tools and even some early forms of glass. The breakthrough for large-format slabs, suitable for countertops and facades, really began in the early 2000s, driven by a demand for more durable and versatile surface materials. Companies invested heavily in research and development, perfecting the precise blend of minerals and the exact temperature and pressure profiles needed to create these large, thin, and incredibly strong slabs. It wasn’t an overnight success; it was years of meticulous experimentation and technological refinement. The initial challenges included achieving consistent color and texture across large pieces, and ensuring the material could withstand the rigors of fabrication and installation. But the perseverance paid off, leading to the high-performance products we see today. It’s a true testament to the power of continuous improvement and pushing the boundaries of what’s possible.

The Evolutionary Leap: Key Properties that Define Sintered Stone

What makes sintered stone so revolutionary? It boils down to a remarkable combination of properties that are difficult to find in a single material.

- Unrivaled Durability: It’s incredibly hard and resistant to scratches, chips, and abrasion. You can chop vegetables directly on it (though I wouldn’t recommend it for your knives!).

- Non-Porous Nature: This is a huge one. Because it’s non-porous, it’s virtually impervious to liquids, stains, and bacteria. No sealing required, ever!

- Heat and UV Resistance: Hot pots won’t scorch it, and prolonged exposure to sunlight won’t cause fading, making it ideal for both indoor and outdoor applications.

- Chemical Resistance: Most household chemicals, acids, and solvents won’t damage its surface, a significant advantage over natural stone.

- Lightweight and Thin: Despite its strength, sintered stone can be produced in very thin formats (as little as 3mm), making it lighter and easier to handle and install than many traditional materials, especially for large-format applications like wall cladding.

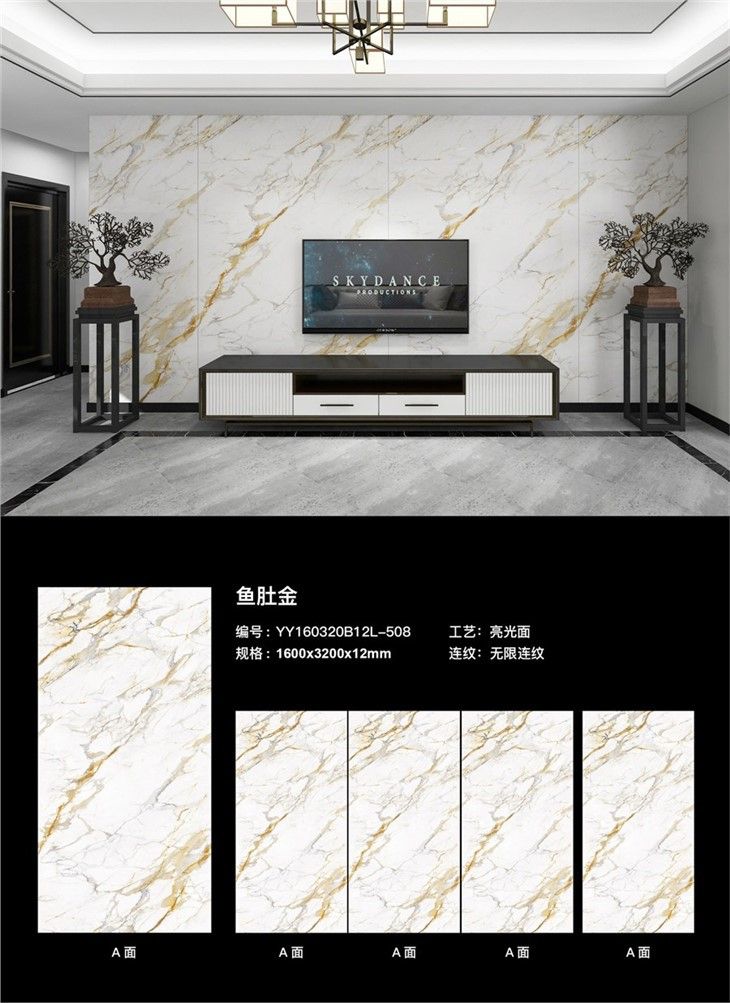

- Aesthetic Versatility: It can replicate the look of natural stone, concrete, metal, wood, and even abstract designs with incredible fidelity. The design possibilities are practically endless. This versatility is what really sets it apart, allowing designers to achieve practically any look they envision. It’s like having a chameleon that can take on any appearance, all while maintaining its superior performance.

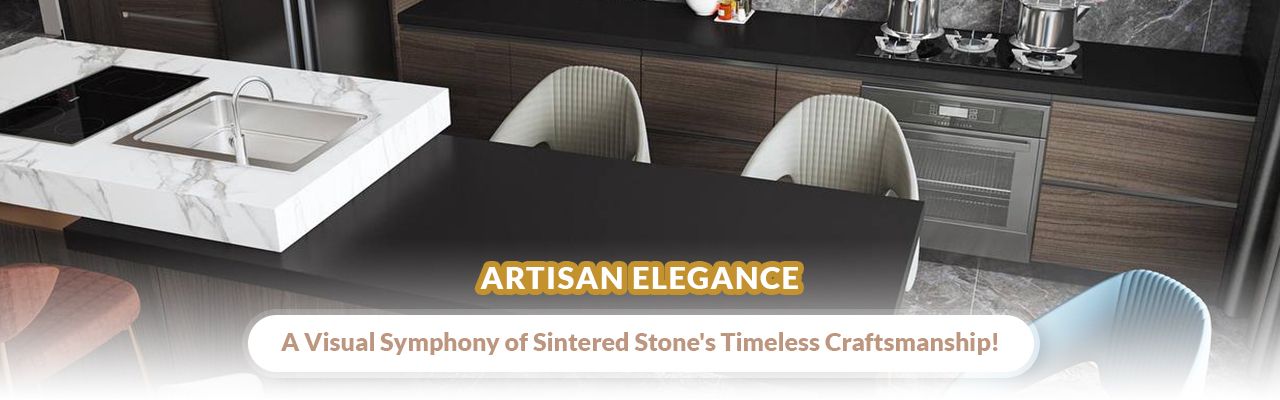

Applications Across the Spectrum: Where Sintered Stone Shines

The exceptional properties of sintered stone have opened up a vast array of applications across both residential and commercial sectors.

- Kitchen Countertops and Islands: Its stain, scratch, and heat resistance make it a dream come true for busy kitchens.

- Bathroom Vanities and Shower Walls: The non-porous nature prevents mold and mildew, ensuring a hygienic and easy-to-clean surface.

- Flooring: High-traffic areas benefit from its extreme durability and low maintenance.

- Exterior Facades and Cladding: Its UV resistance and ability to withstand extreme weather conditions make it perfect for building exteriors, offering both protection and striking aesthetics.

- Furniture and Tabletops: Its thin profiles and wide range of finishes make it a popular choice for custom furniture pieces.

- Commercial Spaces: From retail stores and hotels to restaurants and offices, sintered stone provides a durable, elegant, and low-maintenance solution for high-traffic environments. I’ve seen it used in some truely stunning hotel lobbies, where it stands up to constant use without showing wear. It’s a material that truly performs under pressure, both literally and figuratively.

Fabrication and Installation: A Craft Requiring Precision

While sintered stone is incredibly durable, it does require specialized knowledge and equipment for proper fabrication and installation. Unlike softer materials, it demands diamond-tipped tools for cutting and shaping. The large format slabs also require careful handling to prevent breakage before installation. Skilled fabricators understand the nuances of working with this material, ensuring precise cuts and seamless joins. Installation often involves specialized adhesives and sometimes mechanical fastening systems, especially for vertical applications like facades. It’s not a DIY project for the faint of heart, but when done by experienced professionals, the results are truly spectacular. This is where the ‘elegant spaces’ part of the story really comes alive, as the precision in fabrication ensures a flawless finish. A small miscalculation here can ruin a whole slab, so attention to detail is paramount.

The Future is Sintered: Sustainability and Innovation

The journey of sintered stone is far from over. Manufacturers are continually innovating, developing new textures, finishes, and even sustainable production methods. Many sintered stone products are made from natural, often recycled, materials and the manufacturing process itself can be quite energy efficient, with some companies utilizing renewable energy sources. Its longevity also contributes to sustainability, as it reduces the need for frequent replacement. Looking ahead, we can expect even more intricate designs, lighter and thinner formats, and perhaps even integrated smart technologies within the surfaces themselves. Sintered stone is not just a material; it’s a platform for future innovation in architecture and design, constantly adapting and evolving to meet the demands of a changing world. It’s a material that truly embodies the idea of ‘built to last,’ which is a key component of sustainable design. And who knows, maybe one day it’ll be printed right in our homes!

From the raw embrace of Earth’s minerals to the elegant, sophisticated spaces it now defines, sintered stone has carved out a unique and indispensable niche in the world of surface materials. It’s a testament to human ingenuity, taking natural processes and accelerating them to create a product that offers unparalleled performance and aesthetic freedom. Its journey from a niche product to a mainstream choice for designers and homeowners alike is a story of continuous innovation and a commitment to excellence. As we continue to seek materials that are both beautiful and resilient, sintered stone stands as a shining example of what’s possible when we blend scientific understanding with artistic vision. It’s more than just a surface; it’s a foundational element for the spaces of tomorrow, built to endure and inspire for generations to come. It truly is a remarkable material, and one that will only continue to grow in popularity as its benefits become more widely understood. The future of design is undoubtedly paved, or perhaps, surfaced, with sintered stone.