Picture this: You’re hosting a dinner party, and suddenly your guests need more space. Instead of scrambling to move furniture, your wall-mounted dining table smoothly unfolds like magic. What’s behind this seamless transformation? It’s not just clever design—it’s the result of decades of engineering innovation.

Wall-mounted dining tables have evolved far beyond simple storage solutions. Today’s systems represent sophisticated engineering marvels that blend functionality with aesthetics. These ingenious setups transform cramped spaces into versatile dining areas, but achieving that smooth operation requires understanding some fundamental mechanical principles. Whether you’re planning a renovation or simply curious about how these systems work, there’s more to these tables than meets the eye.

The Foundation: Pivot Points and Load Distribution

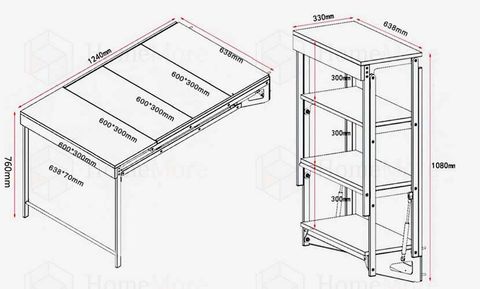

Every successful folding dining table system starts with smart pivot design. Engineers must carefully calculate where forces will act when the table extends and retracts. Think about how a door hinge works, but multiplied across multiple connection points. The pivot points must distribute weight evenly to prevent wobbling or binding during operation. Professional systems often feature precision bearings that allow smooth rotation while handling substantial loads. A typical dining table might need to support 50-100 pounds when extended, plus additional weight from chairs and food. The secret lies in using high-quality ball bearings and ensuring proper alignment between all moving parts.

Spring Systems and Counterbalance Mechanics

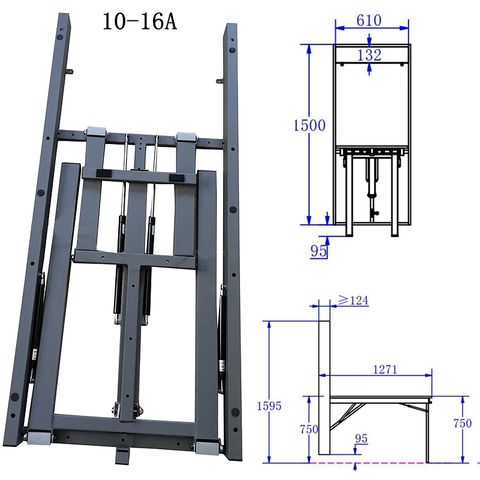

Here’s where things get really interesting: the counterbalance mechanism. Most effective wall tables incorporate spring-loaded systems that help users extend and retract the table with minimal effort. These springs aren’t just random components—they’re precisely calculated to offset the table’s weight. Imagine trying to lift a 60-pound table by hand; now picture having a spring assist that makes it feel almost weightless. This counterbalancing principle reduces stress on the mounting hardware and makes operation effortless. Some systems even use gas pistons instead of traditional springs, providing consistent performance over time. The engineering challenge is finding the right balance—too much assistance and the table feels unstable, too little and it becomes difficult to operate.

Material Science and Structural Integrity

What happens when you put a table against a wall? The materials used become critical. Modern systems often combine aluminum frames with engineered wood or composite surfaces. Aluminum offers excellent strength-to-weight ratios and corrosion resistance, making it ideal for mounting hardware. The table surface itself needs to handle both flat and extended positions without warping or cracking. Many manufacturers use laminated materials or specialized woods that maintain their shape under stress. The joints between table sections must be strong enough to support daily use while allowing smooth movement. Engineers consider factors like thermal expansion, humidity changes, and impact resistance when selecting materials. For instance, a table that expands and contracts with temperature changes could develop gaps or misalignments if not properly designed.

Safety Features and User Experience Considerations

Smooth operation isn’t just about mechanics—it’s about user safety and comfort. Every quality system includes features like soft-close mechanisms that prevent slamming, safety stops that prevent over-extension, and secure locking systems. These aren’t just nice-to-haves; they’re essential for preventing damage to the table, wall, or users. Some advanced systems even include sensors that detect obstacles and automatically stop movement. The engineering behind these safety features involves careful consideration of timing, force limits, and fail-safe mechanisms. A well-designed system should operate quietly, respond predictably, and provide tactile feedback to users. Imagine accidentally bumping into a table that suddenly extends—this is why safety controls matter so much.

Installation and Mounting Hardware Precision

Even the best-designed system can fail if installation isn’t done correctly. The mounting hardware plays a crucial role in overall performance. Engineers design mounting brackets to handle both static and dynamic loads. Static loads refer to the table’s weight when stationary, while dynamic loads account for movement and user interaction. Proper wall attachment requires understanding structural elements like studs and load-bearing walls. Many systems come with detailed installation guides and require professional installation for optimal results. The mounting points must be positioned to allow full extension without interference from the wall or surrounding fixtures. Some installations even require reinforcing the wall structure to handle the forces involved.

Maintenance and Longevity Factors

Finally, no engineering solution is complete without considering long-term performance. Quality folding systems are built to last, but they require attention to keep operating smoothly. Regular maintenance of pivot points and spring mechanisms can extend lifespan significantly. Dust and debris can cause wear in moving parts, so keeping systems clean matters. Some manufacturers recommend periodic lubrication of moving components, while others design systems that require virtually no maintenance. The engineering philosophy here is about creating redundancy—multiple backup systems and wear-resistant components. Understanding how these systems age helps engineers improve future designs and provides users with realistic expectations about performance over time.

The engineering behind smooth folding dining table wall systems reveals how thoughtful design can transform ordinary spaces into extraordinary solutions. From the careful selection of materials to the precise calculation of counterbalance forces, every element contributes to seamless operation. These systems demonstrate how mechanical engineering can enhance everyday living, making efficient use of space while maintaining aesthetic appeal. The next time you see one of these tables in action, remember that what appears effortless is actually the result of decades of refinement and innovation. Whether you’re planning to install one yourself or simply appreciate the ingenuity involved, understanding these principles adds depth to our appreciation of these practical marvels.