Have you ever wondered how those elegant dining tables seem to magically expand when you need more seats? It’s not magic at all – it’s the result of decades of clever engineering. These tables are like architectural puzzles, each component carefully designed to work in harmony. The secret lies not just in the wood or metal, but in the intricate mechanical systems that allow them to transform from compact to expansive with ease.

Modern extendable dining tables have become a staple in homes across the globe, offering the perfect solution for entertaining guests while maintaining a comfortable living space. But beneath their sleek exteriors lies a world of mechanical ingenuity that many people never stop to consider. These tables aren’t just pieces of furniture – they’re marvels of engineering that combine aesthetics with functionality. Whether you’re looking to host a dinner party or simply want extra seating for family meals, understanding how these tables work can help you appreciate their design even more. The marriage of form and function in extendable dining tables represents one of the most successful applications of mechanical engineering in domestic furniture.

The Basic Principles of Extension

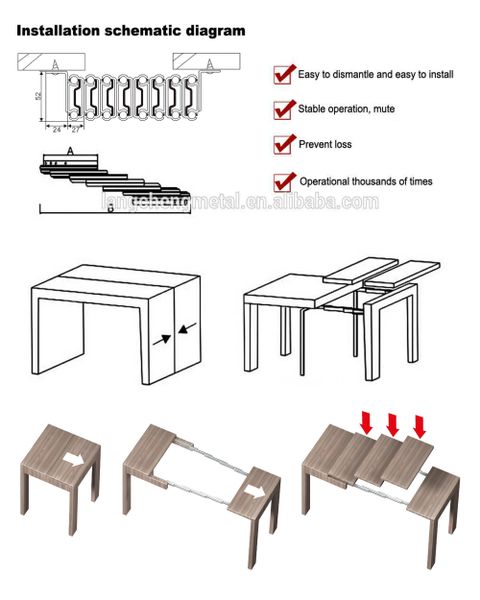

At its core, extending a dining table is all about creating additional surface area without sacrificing structural integrity. The fundamental concept relies on two main approaches: sliding extensions and folding extensions. Sliding mechanisms work much like a drawer – the extension moves along a track, adding length to the existing table surface. This method requires precision manufacturing to ensure smooth operation and proper alignment. Folding extensions, on the other hand, typically involve hinged sections that fold out from the main table frame. Think of it like opening a book – each panel rotates outward to create new surface area. Both methods must account for weight distribution, stability, and the forces that occur during expansion and contraction. The key challenge engineers face is balancing these competing requirements while keeping costs reasonable for consumers.

Track and Rail Systems Explained

One of the most common sliding mechanisms uses a track and rail system. These tracks are typically made from aluminum or steel and are designed to guide the extension piece smoothly back and forth. The rails slide within these tracks, often incorporating small wheels or bearings to reduce friction. Some high-end tables feature multiple tracks to support heavier loads or provide better stability. The engineering behind these systems is surprisingly sophisticated. The tracks must be precisely machined to ensure the extension moves perfectly straight, while the rails need to be strong enough to handle the weight of the table top and any items placed upon it. You might notice that some tables have a slight gap between the extension and the main table – this is intentional, allowing for thermal expansion and preventing binding as materials change with temperature and humidity.

Hinge and Pivot Mechanisms

When tables fold rather than slide, they rely heavily on hinge and pivot systems. These mechanical joints must be both strong and flexible enough to withstand repeated use over many years. The most common type uses concealed hinges that are built into the table frame. These hinges are often made from stainless steel or other durable materials that resist corrosion. The pivot points are engineered to minimize wear while maximizing the range of motion. Some tables incorporate spring-loaded mechanisms that help the extension panels return to their original position automatically. The angle at which these panels extend can vary significantly, with some designs providing a nearly seamless transition between table surfaces. Engineers must calculate exactly how much force is needed to open and close these mechanisms, ensuring they’re easy enough for anyone to operate but sturdy enough to hold their position under load.

Weight Distribution and Structural Integrity

Perhaps the most critical aspect of extendable table design is maintaining structural strength throughout the entire range of motion. When you add an extension, you’re essentially doubling the surface area, which means the weight distribution changes dramatically. The engineers must design the table so that stress is evenly distributed across all connection points. This involves careful consideration of materials and joint locations. Many modern tables use reinforced corner brackets or additional support beams that activate when the table extends. The thickness of the tabletop itself becomes crucial – a standard 1-inch thick board may need to be 1.5 inches or more when extended to handle the increased span. Real-world testing reveals that tables often fail at the weakest connection point, so designers must identify and strengthen these vulnerable areas before production begins.

Safety Features and User Experience

Good engineering isn’t just about making things work – it’s about making them safe and user-friendly. Modern extendable tables incorporate numerous safety features that prevent accidents or damage. Soft-close mechanisms are becoming increasingly popular, using hydraulic dampers to slow the closing speed of extensions. This prevents slamming that could damage the table or injure someone. Many tables now include locking mechanisms that prevent accidental retraction when the table is in use. Some even feature warning labels or visual indicators showing maximum load limits. The ergonomics of the extension mechanism itself matter enormously – handles should be positioned for easy gripping, and the force required to operate the table should be reasonable for average users. Consider how many times you’ve tried to open a heavy table and found it difficult – that’s where good design makes all the difference.

Materials Science in Table Construction

The materials used in extendable tables play a crucial role in their performance and longevity. Wood remains popular for its warmth and aesthetic appeal, but it requires special treatment to handle the stresses of extension. Engineered woods like plywood or MDF offer better dimensional stability, making them ideal for table tops that must maintain flatness during movement. Metal components, particularly aluminum, are favored for tracks and support structures because they’re lightweight yet strong. Steel offers even greater strength but adds significant weight to the overall design. The choice of materials affects everything from cost to maintenance requirements. For instance, a table with all-metal components will be more durable but potentially more expensive. Some manufacturers now use composite materials that combine the best properties of different substances. The interaction between materials becomes particularly important when dealing with environmental factors like humidity and temperature changes that can cause expansion and contraction.

The next time you enjoy a meal at an extendable dining table, take a moment to appreciate the engineering genius that makes it all possible. These tables represent the perfect fusion of mechanical precision and practical design. From the carefully calculated track systems to the thoughtful placement of support beams, every element serves a purpose beyond mere appearance. Understanding these principles helps us better value these remarkable pieces of furniture and makes us more informed consumers. Whether you’re buying a new table or simply wondering how it works, recognizing the mechanical artistry behind extendable dining tables adds a new dimension to our appreciation of everyday objects. After all, the best engineering solutions are often those we barely notice – they just work flawlessly, making our lives easier and more enjoyable.

![Extendable Dining Table Mechanisms: Types & How They Work [September 2025] for Modern Extendable Dining Table Mechanism](https://northcarolinafinearchitecture.com/wp-content/uploads/2025/10/extendable-dining-table-mechanisms-types-how-they-work-september-2025-for-modern-extendable-dining-table-mechanism.webp?width=480&f=jpg)

![Extendable Dining Table Mechanisms: Types & How They Work [September 2025] throughout Understanding the Mechanics Behind Modern Extendable Dining Tables](https://northcarolinafinearchitecture.com/wp-content/uploads/2025/10/extendable-dining-table-mechanisms-types-how-they-work-september-2025-throughout-understanding-the-mechanics-behind-modern-extendable-dining-tables.webp?width=480&f=jpg)