Building with a 36" metal column kit is a great project, but sometimes, those little gripping disks can give you big headaches. They’re crucial for stability and strength, and when they aren’t working right, your project can quickly stall. Don’t worry, though – you’re not alone, and there’s almost always a fix. This guide will walk you through the most common issues, and show you how to solve them, so you can keep building with confidence. We’ll cover everything from initial setup mistakes to long-term maintenance tips, making sure you have a solid understanding of how to keep those disks working smoothly and your project standing tall. And, just so you know, I’ve been there – countless times. Let’s dive in.

So, you’ve got your 36" metal column kit, and you’re ready to start building. That’s awesome. These kits are super versatile and can be used for a bunch of different applications. However, one of the most common points of trouble for builders, whether they’re beginner or seasoned pros, are the gripping disks. These small, yet mighty components are vital for ensuring the structural integrity of your column. They create friction, providing the grip that holds everything together. But what happens when they don’t grip? Or when they come loose? That’s where this guide comes in. We’ll explore the most frequent problems, offer practical advice, and share some real-world examples to help you troubleshoot and correct the issues with your gripping disks. Get ready to become a gripping disk guru!

Understanding the Gripping Disk’s Role

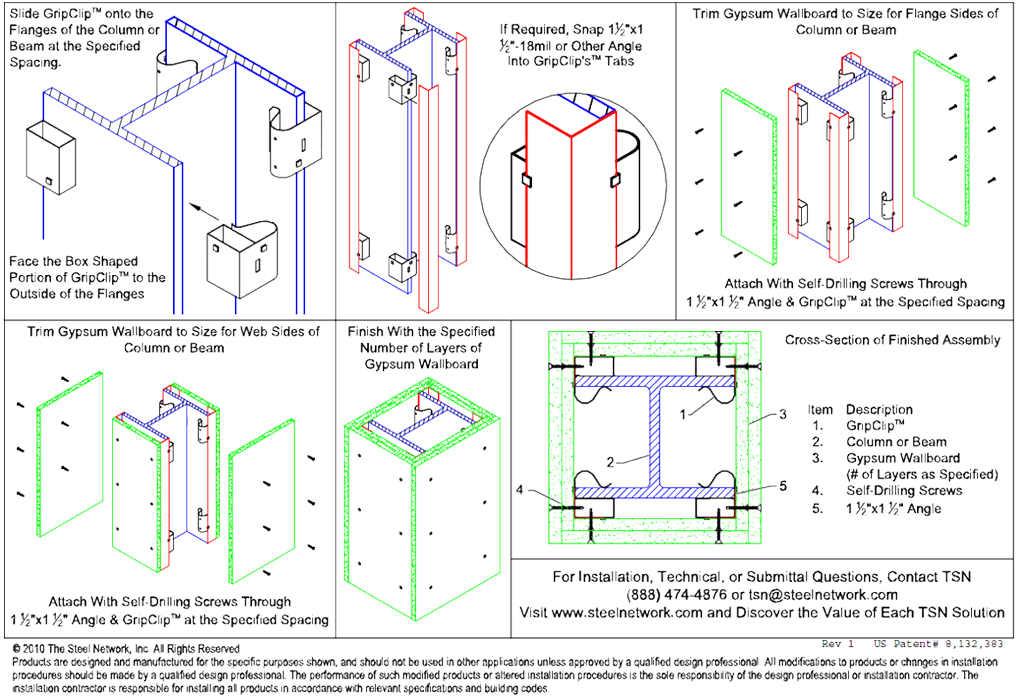

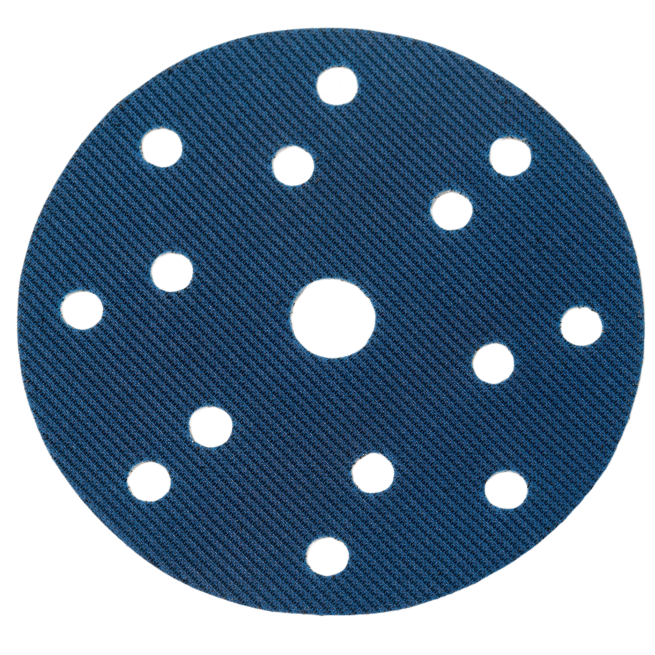

Before we jump into fixing problems, it’s important to understand why these disks are so important. Think of them like the teeth of a gear. They provide the grip, or the friction, that prevents the metal column sections from slipping or rotating. This friction is created when the disks press against the internal surfaces of the column sections. The quality of the material, the design, and how the disks are installed all contribute to how well they function. Without proper gripping, your column could be unstable, wobbly, and potentially unsafe. So, understanding their function is the first step to troubleshooting any problems you might encounter. A well-gripped column is a strong column, after all.

Common Problem #1: Improper Installation

This is, hands down, the biggest culprit. Incorrect installation is the root of many gripping disk woes. Here are some common mistakes, and how to fix them:

- Wrong Orientation: Gripping disks often have a specific “up” and “down” orientation (sometimes it’s very difficult to tell, I know.). Make sure you’re inserting them in the right direction. Check the manufacturer’s instructions; they usually show this pretty clearly.

- Not Enough Disks: Some kits require a specific number of disks per section. Not using enough will reduce the grip and overall stability. Double-check your kit’s specifications.

- Forcing the Fit: If you’re having to force the column sections together, something is likely wrong, and you’re probably damaging the disks. Back up, re-evaluate, and see if you can identify the issue. Sometimes, a tiny burr in the metal can cause problems.

- Using the Wrong Size: Ensure you are using the correct size gripping disk for your specific column kit. Using the wrong size will result in a poor or non-existent grip.

Common Problem #2: Damaged or Worn Disks

Over time, the gripping disks can wear down, especially if the column is frequently disassembled and reassembled. They can also be damaged during installation if you’re not careful, like if you are forcing the sections together. Here’s what to look for and how to deal with it:

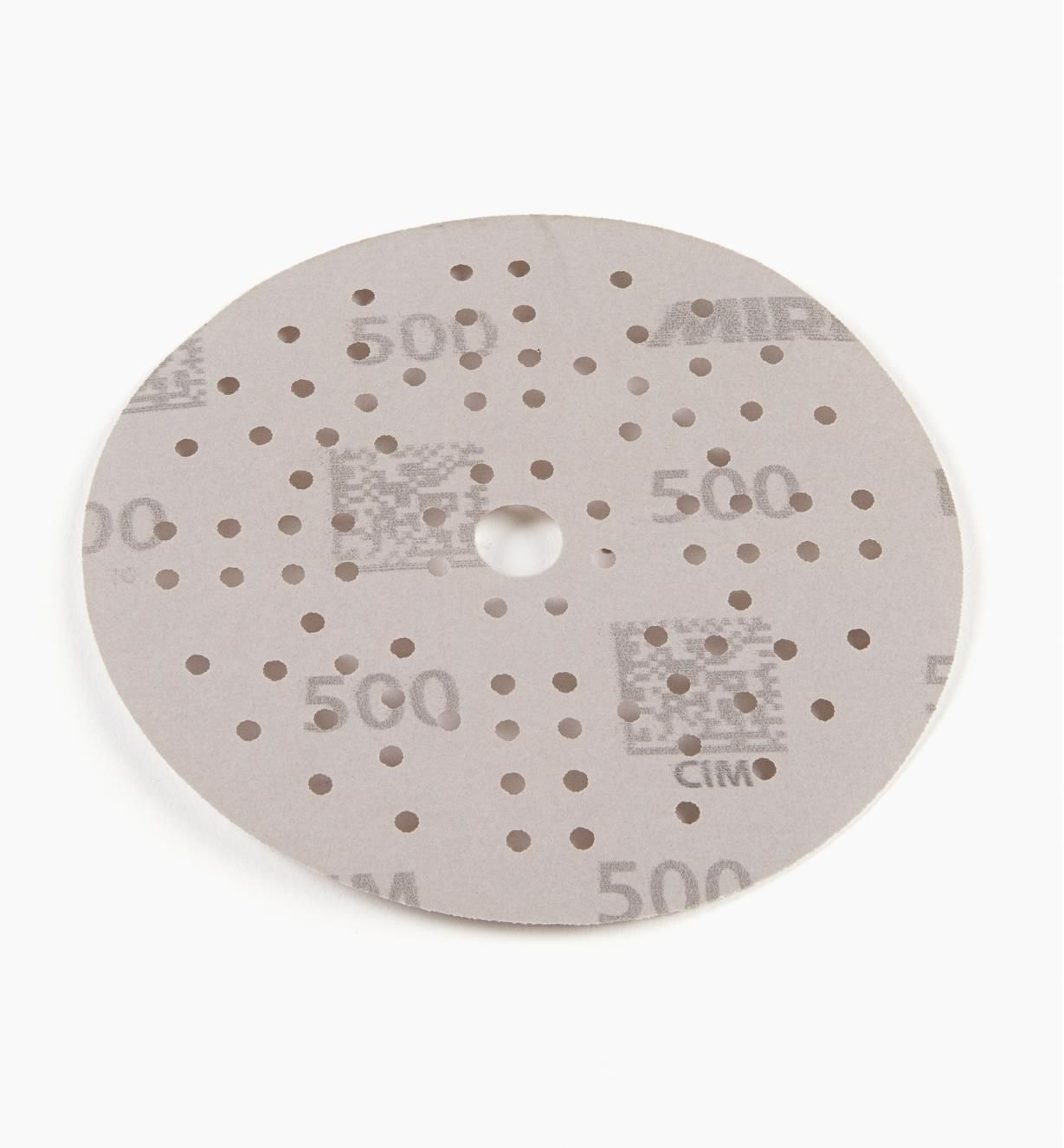

- Visible Wear and Tear: Check the disk surfaces for signs of wear, such as scratches, dents, or a loss of the textured surface (if applicable). If they look worn, it’s time for replacements.

- Material Degradation: Some disks are made from softer materials that may degrade over time. Inspect for cracking, crumbling, or any changes in the disk’s shape or size.

- Replacement is Key: The good news is that gripping disks are usually inexpensive and easily replaceable. Always have a few spares on hand, just in case. Contact the kit manufacturer or a hardware store to buy the replacements.

Pro Tip: When disassembling your column, be gentle. Don’t pry or force the sections apart, as this can damage the disks.

Common Problem #3: Surface Contamination

Even small amounts of oil, grease, or dirt can significantly reduce the friction between the gripping disks and the metal column sections. This leads to slippage and instability. Here’s how to deal with it:

- Cleaning is Crucial: Before assembly, thoroughly clean the inside of the column sections and the gripping disks. Use a degreaser or a mild detergent and water. Be sure to let everything dry completely before reassembly.

- Avoid Lubricants: Do not use any lubricants, like oil or grease, on the disks or the column sections. These will work against the gripping action.

- Work in a Clean Environment: Try to assemble your column in a clean area to prevent dust or debris from contaminating the parts. A clean environment is often the best environment for any project.

Common Problem #4: Misalignment and Warping

If the metal column sections aren’t perfectly aligned, or if they’re slightly warped, the gripping disks won’t be able to make proper contact. This is rare, but it can happen, particularly with lower-quality kits or if the column has been subjected to extreme temperatures or pressure. Here’s what to check:

- Visual Inspection: Carefully inspect the column sections for any signs of bending or distortion. Use a straightedge (like a level) to check for straightness.

- Sectional Alignment: Make sure each section fits flush with the others. If there are gaps or unevenness, the disks won’t grip correctly.

- Repair or Replacement: If you spot any warping or misalignment, you may need to try to correct the problem (carefully bending the metal back into shape) or replace the affected sections. Contact the kit manufacturer for guidance.

Common Problem #5: Loose Fasteners and Assembly Issues

While the gripping disks are the primary source of the column’s strength, other components and the way you assemble them can also lead to problems. Consider these factors:

- Check Fasteners: If your kit uses screws, bolts, or other fasteners, make sure they are tightened to the recommended specifications. Loose fasteners can allow the column sections to shift or rotate, making the gripping disks ineffective.

- Assembly Sequence: Follow the manufacturer’s recommended assembly sequence. Assembling parts in the wrong order can stress the disks, and the column’s overall integrity.

- Leveling: Make sure the column is level during assembly, especially if you’re building on an uneven surface. This will help ensure that the column is straight and the disks are making even contact.

Common Problem #6: Environmental Factors

The environment where your column is installed can also affect the gripping disks. Extreme temperatures, humidity, and exposure to chemicals can all cause problems. Here’s what to consider:

- Temperature Fluctuations: Dramatic changes in temperature can cause the metal to expand and contract, potentially affecting the grip. Make sure the column is designed to withstand the expected temperature range.

- Humidity: Excessive moisture can lead to corrosion, which can weaken the metal and reduce the gripping ability. If the column will be exposed to humidity, consider using a rust-resistant finish.

- Chemical Exposure: Avoid exposing the column to harsh chemicals or solvents, as these can damage the disks and the metal. Always consult the manufacturer’s guidelines for appropriate cleaning and maintenance.

Troubleshooting gripping disk problems in your 36" metal column kit doesn’t have to be a frustrating experience. By understanding the role of the disks, recognizing common installation errors, and paying attention to the condition of the components, you can keep your project stable and secure. Remember to always refer to the manufacturer’s instructions and use common sense. If you’re unsure about anything, reach out to the kit manufacturer or a local hardware store for assistance. With a little bit of care and attention, you can ensure that your column stands strong for years to come. Now go forth and build, and remember, a little bit of patience and attention to detail can make all the difference. Good luck, and happy building.